Air Blow Check Valves

Air blow check valves are designed to protect pipelines against corrosion by evacuating lines of product or Clean-In-Place (CIP) solutions.

The valve works by air pressure pushing the rubber plug away from the seat. When air pressure is absent, the spring holds the valve closed against the seat, preventing product from flowing into the air line.

Air blow check valves work in a variety of applications including evacuation and/or drainage lines for evacuation of product and air stirring products in pipes, storage tanks, and other equipment.

Features & Options:

All stainless steel construction (316L)

Precision molded plug assures positive shut-off

Seat material:

EPDM - 250°F max.

Viton® - 500°F max.

1.0 micron filter

Meets 3-A standards

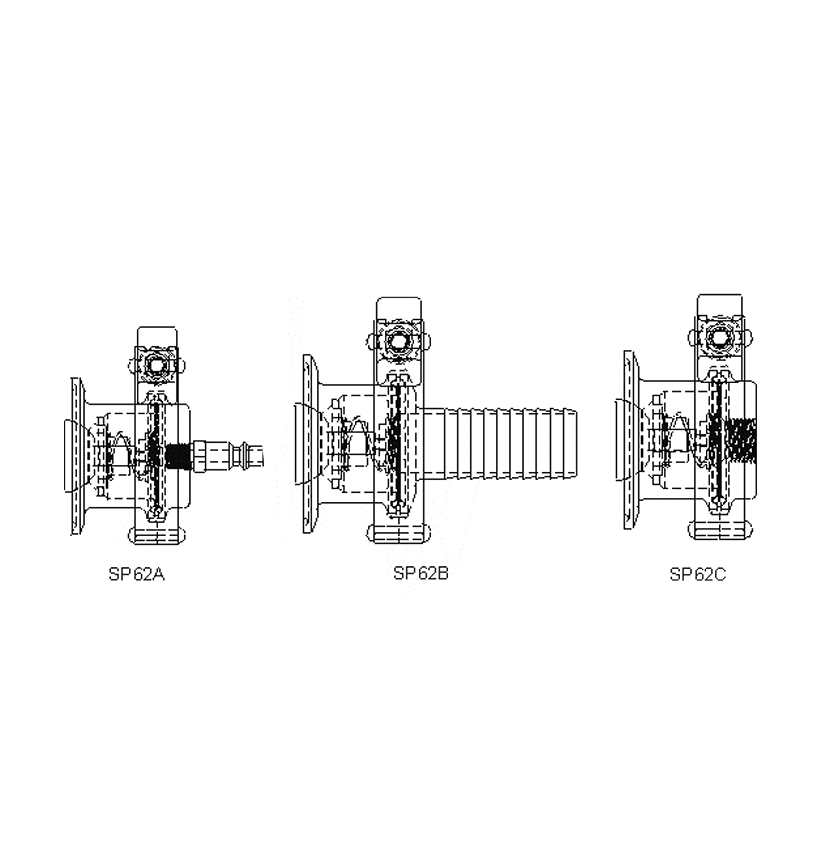

Configurations:

SP62A - Quick coupler adapter

SP62B - 1” rubber hose adapter

SP62C - 3/8” female NPT

Note: when ordering please specify size of clamp connection (1.5” thru 4.5”) and type of inlet adapter.

Note: When ordering air blow check valves with SPI ball check valves, order as follows:

2.5” air blow for 1.5” and 2” ball check valves

4” air blow for 2.5” and 3” ball check valves

4.5” air blow for Tri-Clover® 45BYMP-3